Flashing

Mechanically keyed flashing was created to ensure moisture protection in the masonry field. It is typically used at floor level, underneath sills and over lintels. With 3″ intervals, a bond is formed in the mortar bed in three locations to ensure a watertight seal without the use of other sealants (certain conditions apply). The 3″ intervals provide moisture to exit the structure quickly and unconstrained.

Available In: Copper, Stainless Steel, Terne Coated S.S & Lead Coated Copper

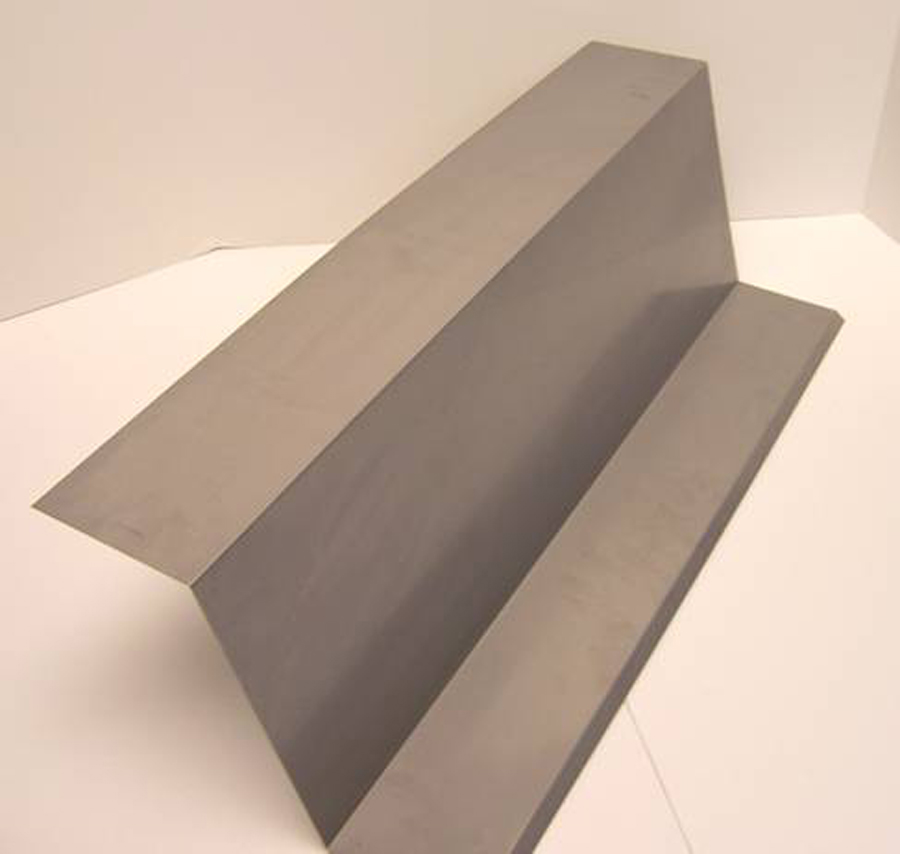

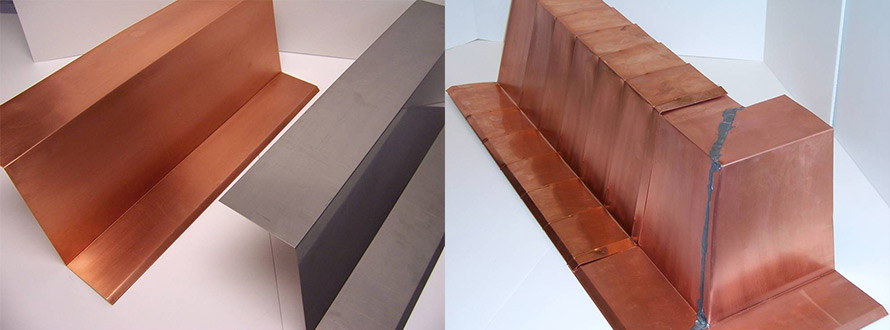

SMOOTH STEP FLASHING

Step flashing is manufactured to your exact specifications.

Available In: Copper, Stainless Steel, Terne Coated S.S & Lead Coated Copper

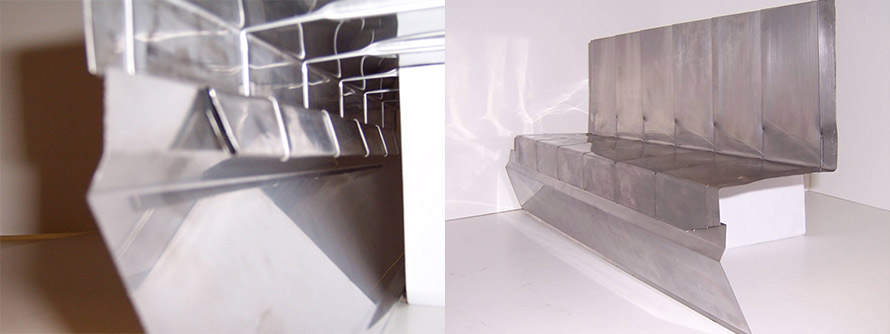

TWO PIECE COUNTER FLASHING

With the same purpose as keyed and smooth flashing, this two piece counter flashing applies where flat roofs meet rising walls. The step flashing, either keyed or smooth, has a vertical locking slot that holds the insert into place. After the step flashing is installed, the insert can be set against the base flashing. The insert can be removed and reused at any time.

Available In: Copper, Stainless Steel, Terne Coated S.S & Lead Coated Copper

THREE-WAY SAWTOOTH THRU-WALL FLASHING

Three-way sawtooth interlocking flashing with a 3/16″ high undercut sawtooth ribs at 3″ centers, provide a three-way mechanical bond in the mortar bed and insure rapid drainage of moisture to exterior. Sawtooth undercuts provide a watertight joint without the use of sealants or solder. Soldering may be required at the corners or in special conditions.

Available In: Stainless Steel, Terne Coated S/S & Lead Coated Copper, Aluminum and Copper

Installation:

- Place a thin bed of mortar on the surface to be prepared for flashing placement.

- Set flashing on mortar bed push down to ensure that the mortar fills the sawtooth keys.

- Set the sawtooth flashing into the mortar.

Always work from left to right

Make sure the end sawtooth key is kept clean to ensure locing of the next section of flashing. Flashing should be secured to substrate.

PREFORMED METAL CORNERS & END DAMS

Preformed metal corners and end dams are used in correlation with other flashing to insure structural reliability by creating a moisture barrier that supports a watertight setting. Preformed metal corners and end dams are seamless, tough and most important, simple. Ordering preformed corners and end dams will eliminate cutting and bending on site.

Available In: Stainless Steel, Terne Coated S/S & Lead Coated Copper, Aluminum and Copper

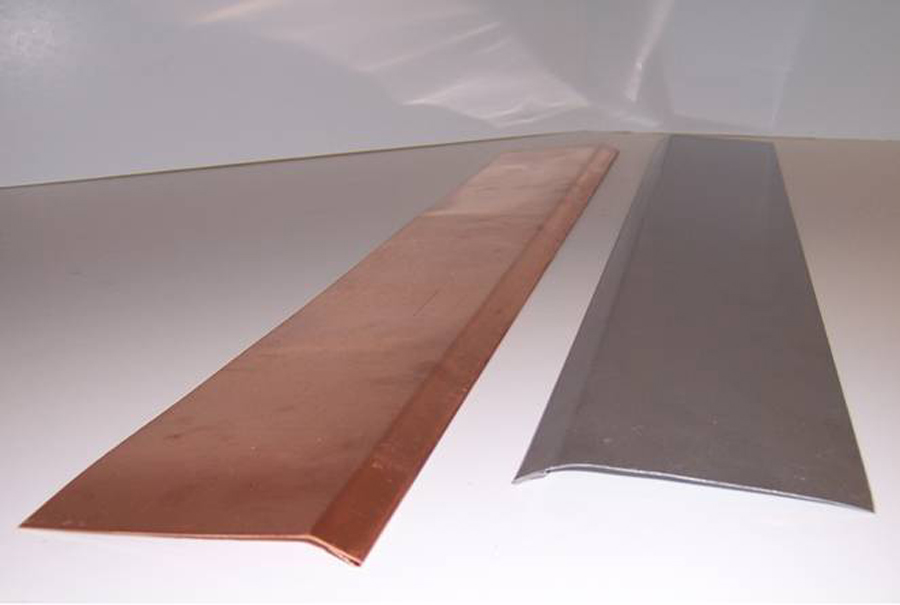

DRIP EDGE

This type of flashing will offer a tough aesthetically and attracting finish for thru wall or exposed flashing applications.

TERMINATION BAR

The termination bar is used to secure flashing to an already existing back up wall or other type of supports.

DOWEL CAPS

Stainless Steel Dowel Caps are used when flashing is penetrated below coping stone in order to prevent moisture infiltration.